Page 4 of 7

Posted: Tue Jun 16, 2009 11:15 pm

by milesdzyn

I found the vacuum leak today, Intake manifold seal blowout. I put on the spare set of carbs and got all 4 cylinders firing smoothly, more on this in another thread.

The door holes will have flat sheet metal welded in for now, untill I can get some original side panels to cut and weld in for a more factory finish.

If anyone has some of the side panels off a K top I need some.

Just need to tune her up and find some reasonable insurance here in Vegas. The rest of the work will continue here and there.

Miles

Posted: Sat Oct 17, 2009 12:25 am

by milesdzyn

Well it's been a while since the last update and there have been a lot of design changes on the interior which will be revealed soon.

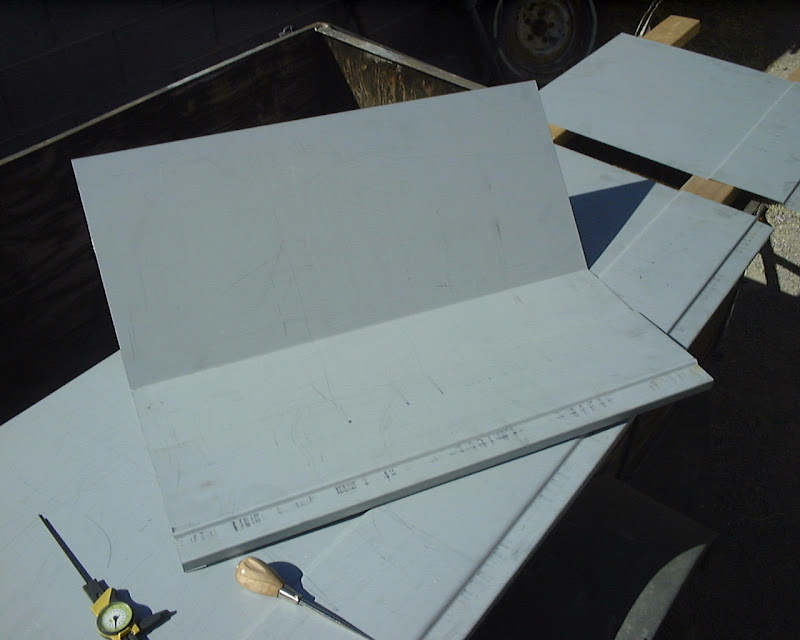

I also decided that the side panels need to match the original design, so I worked out a way to bend it up myself.

First I bent up a test sample, and then started bending.

I had to raise the pieces in the break press, with a 1/8" steel plate, in order to get the tight chamfer bends.

I'm really happy with how the panels came out, but I still have to cut the panels to fit the contour and weld them in. More pictures and updates to follow on these panels.

Miles

Posted: Sat Oct 17, 2009 8:51 am

by dr4yrk9

that is just amazing, pretty cool that you can do all that. I cannot wait to see the finished product. Great job.

Posted: Sat Oct 17, 2009 9:07 am

by M Wehrman

Very nice!

Mark

Posted: Sat Oct 17, 2009 10:44 am

by chacaocop1

Great panels!!! Just weld them in!!! We want to see!!!

Posted: Sat Oct 17, 2009 2:10 pm

by David Dunn

Miles,

Great work. I am glad to see someone take the time and effort to put the structural folds into the panels.

Posted: Sun Oct 18, 2009 5:40 pm

by Erik712m

Miles, Looks great.

Posted: Tue Oct 20, 2009 1:24 am

by milesdzyn

Thanks guys.

Fitted one of the panels and thou I can adjust them a little more during the welding, they fit pretty good. Not bad for a first time metal fabrication on a $50.00 bender.

I won't start welding untill all the panels are cut to fit, still have the fronts to do.

Sometimes I wish I could just do some things the easy way.

It would make life a lot easier.

Miles

Posted: Tue Oct 20, 2009 5:04 am

by pcolette

Very nice job! I'm impressed!

I also see a new toy in my future - a bender. Where did you get yours?

Keep up the great work - and thanks for the photos.

Paul

Posted: Tue Oct 20, 2009 7:56 am

by andy

How cool is that! Nice piece of work Miles.

Andy

Posted: Tue Oct 20, 2009 9:39 am

by chacaocop1

I bow to you, oh great Miles....

Thanks for those pics. It really shows the details very good. Without a doubt a great job. Congrats.

Posted: Tue Oct 20, 2009 9:48 am

by EvanH

Wow - you guys are about two steps shy of proposing marriage!

Seeing Miles' work fills me with motivation. I wonder if he could fill my bank account, too?

-Evan

Posted: Sun Jul 11, 2010 8:20 pm

by milesdzyn

Long time overdue update.

Been holding off welding the side panels so I would have access through the open holes.

Finished off the welding on the cab barrier with lockable access/ exit door for security, will make another door with wire mesh and insect screen for air flow.

Couldn't find a rear upper door so I made my own. Will add the rest of the vent hardware when final paint is done.

Got the driver side panels welded in but not finished.

Also got the side rub rails going, but more on that later, if anyone wants to see more detailed pics go here:

http://picasaweb.google.com/pinzgauer.d ... /BodyWork#

Going slow due to the heat 108 degs average as of late, only get to work for a short time early in the mornings.

Miles

Miles pinz restoration

Posted: Mon Jul 12, 2010 12:01 am

by krick3tt

Miles,

Where did you find the vents for the rear door? Been looking for something like that.

Morris

Posted: Mon Jul 12, 2010 8:41 am

by Pinzgauer Pete

Excellent work in all facets of this restoration, I am particularly impressed with the fabrication work, when a part wasnt readily available you simply figured out a way to make one, and your attention to detail allowed for a almost factory standard. Panels that originally were made in a hydrolic press with factory molds you made painstakingly by hand. I can see you are one of those guys that holds himself to a high standard. I can imagine all the panels you made that might have been a fraction off but were cast to the wayside because to your eye they were unacceptable before you finally got it to a level you could live with, and even those you most likely still have flaws in your eyes. When this project is completed you will have a basically one of a kind vehicle that you can be extremely proud of. Thanks for sharing the pics and commentary, and expieriences.