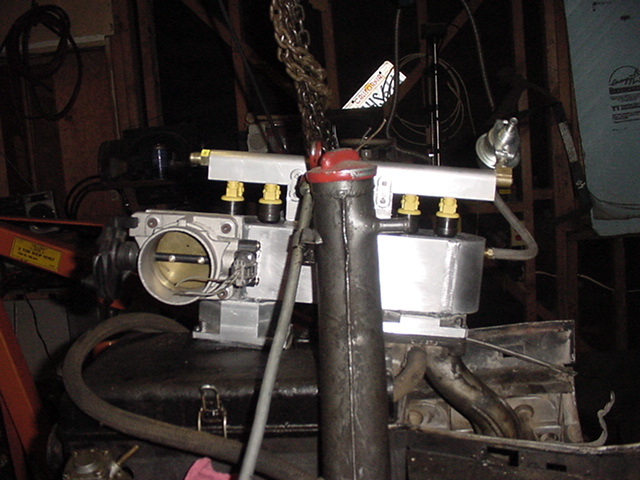

Looks like a nice bolt on system. And using an off the shelf controller is a perfectly reasonable design decision.

One comment regarding the Megasquirt:

Jim LaGuardia wrote:NO

Mega squirt is more suited to dual throttle bodies.

Lot's of misinformation about the megasquirt out there. Bottom line is the original versions will handle port injection, throttle body injection, Independent Throttle Body, whatever.

What the Megasquirt V1 does not do is sequential injection, they will do batch or bank fire. Which for the pinz is really all you need. Yup, it will drive your 4 injectors, and you can bank fire them in pairs of two, etc. Later versions do sequential, but most have found it's simply not worth the expense & complexity.

Why do we not need sequential? Lot's of reasons:

- The nice bolt on plenum/injector system above is using the factory intake. It's an ideal approach for the pinz. But the factory intake has unequal length runners. Which makes the whole idea of timing the injection pulse to the open valve is simply not realistic. It will vary with RPM, and cylinder. You might could justify it with true port injection with the injector near the valve. But with the "wet-runner" approach the pinz is ideal for, (and the photo above shows) it's un-realistic.

- But what about per cylinder trim? Again, you have unequal length runners, and an unequal air feed with the Throttle/butterfly at one end of the plenum. A far better approach is to trim the airflow properly with the plenum design. Trimming the fuel will work, but is simply covering up the core problem, unequal air flow. Independent throttle bodies with exact air trim is probably the best approach, and what you see on critical performance applications. You'll see ITB on bikes for many reasons.

- But what about power? Let's be real.... the pinz valve design is the limiting factor. Add to that a very non-optimal intake runner design (I've done the math, they are too short for the engine torque curve/rpm range). Mfg's use sequential because they have to, it allows them to tweak the emmissions a bit more. But it's not power. Lot's of high power corvette engines on the road with bank fire injectors shooting at 90 degrees into the runner wall.

Put it in perspective: There are land speed records being made with batch fire Megasquirts combined with the ford EDS ignition modules.

What's the downside of sequential? Several:

- yet another sensor to engineer, tune, and possibly fail. Cam position sensors are much more complicated to engineer aftermarket. You can run a batch/bank fire with just a MAP sensor & rpm trigger, and can limp home even without one of those. Not true with sequential.

- Expense. Big time. More parts, more engineering, and much higher $$$ controllers. Myself, I think this is why aftermarket tuners pump sequential so much, it allows them to sell more expensive controllers, more dyno time to tune, etc.

To me, the real test of this is if a tuner will sell their plenum/intake/plumbing without a controller. Or as a lower cost, but lower power batch system. The reason you don't see a lower cost batch option offered usually is that in most cases there is minimal power/drivability difference between the two.

Don't get me wrong, the plenum/injector parts above are very neat, and I hope there are many sold. A bolt on system like this is ideal for the hobbiest. You'll still need to tune it, due to differences in engine compression/backpressure/air filter, etc. So while pre-configured maps are great starting points, you'll still need to tune.

In my first home-made EFI experiments, I went to lot's of trouble to try to pre-load the maps based on torque curves, etc. What I learned is the Megasquirt is so intuitive to tune that it was wasted effort. My first test mule vehicle (fiat spyder) started the 1st time I tried, and was idling smoothly with about 2 minutes of fiddling. within 10 minutes of road tests, it was smooth and very drivable, beating carb performance. Could I have refined it on a dyno? Absolutely. Was I at optimal power? Probably not. But I was way ahead of carbs, and tweaking over a couple of weeks dialed it right in.

This looks like great progress, and it will be neat to see how many make it on the road, what the real advantages are, etc.

Again, my comments are not meant to be critical, but more educational. The whole "sequential is better/faster/needed" theme is a bit of a pet peeve which does not jibe with the engineering.

If you have sequential working and don't mind the expense/MTBF risk, then drive it and enjoy the advantages of EFI!

Have fun,

Alan